Sustainable

operation

102-9, 204-1, 308-1, 414-1

Sustainability is a key element in our operation. As part of Grupo Proeza we are committed to S“Complying with environmental regulations, following international best practices, and using natural resources sustainably”

Grupo Proeza’s Code of Conduct

Responsible supply chain

102-40, 103-1, 103-2, 204-1

We are committed to extend our sustainability approach to our value chain. In 2021, all our new suppliers were assessed with social and environmental criteria through our supplier risk assessment.”

Two new suppliers have committed to reducing their environmental footprint, and due to our high standards, none of our suppliers is at risk of hiring child or forced labor.

We are aware of the importance of suppliers in our Sustainability Performance. Therefore, one of our goals is to promote a responsible and compliant behavior throughout our supply chain.

Key purchased products

Steel, extruded aluminum, fasteners, welding wire, wire forms, metallic stamping parts and chemicals for coating

Metalsa Supplier Business Assessment

102-9, 103-1, 103-2, 103-3

All our suppliers are evaluated and selected based on an assessment that includes topics regarding quality, employment conditions, human rights, ethics, corporate governance, legal compliance, sustainability, as well as criteria aligned to institutions and standards such as the International Automotive Task Force (IATF) and the Automotive Industry Action Group (AIAG), ISO 14001:2015.

Our Procurement Group delivers a world-class supply base that enables innovation-driven solutions that foster sustainable growth and add value to all our stakeholders. We have developed a strategy to enhance our supply chain and drive it towards innovation and sustainability.

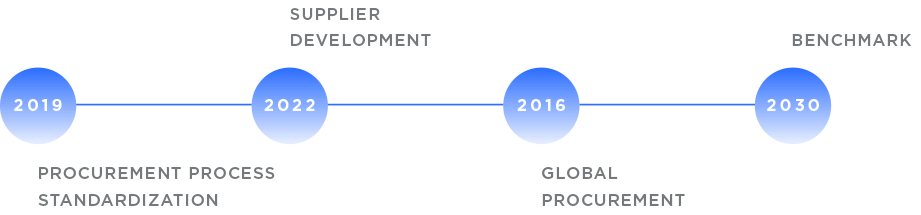

Supply Chain Roadmap 2030

In addition, we developed a Supplier Manual that establishes behavior, ethics and sustainability guidelines for our suppliers to comply:

Metalsa Supplier’s Manual

Proeza’s Code of Conduct provides guidelines to conduct our commercial relations with integrity, fairness and respect in all countries where we have operations. In addition, our Supplier’s Manual defines the requirements and expectations from Metalsa’s suppliers regarding compliance, ethics, sustainability, health and safety. The Manual provides an overview of Metalsa’s understanding of sustainability as well as detail on the 10 principles of the UN Global compact that suppliers are required to follow. The Manual also provides guidelines to respect human and labor rights and Metalsa’s Environmental Policy.

Support program for SMEs

We aim to positively impact the communities where we operate and have implemented a supplier support program for SMEs to help them face the COVID crisis. The program includes benefits such as advance purchases, reduction of payment timeframe, and tailored support.

Our suppliers can also benefit from the new Development Program for SMEs that consist of:

Financial support

Advisory support

Training and capacity building

With these programs, we want to ensure our suppliers develop along with us in terms of growth and positioning in the sector.

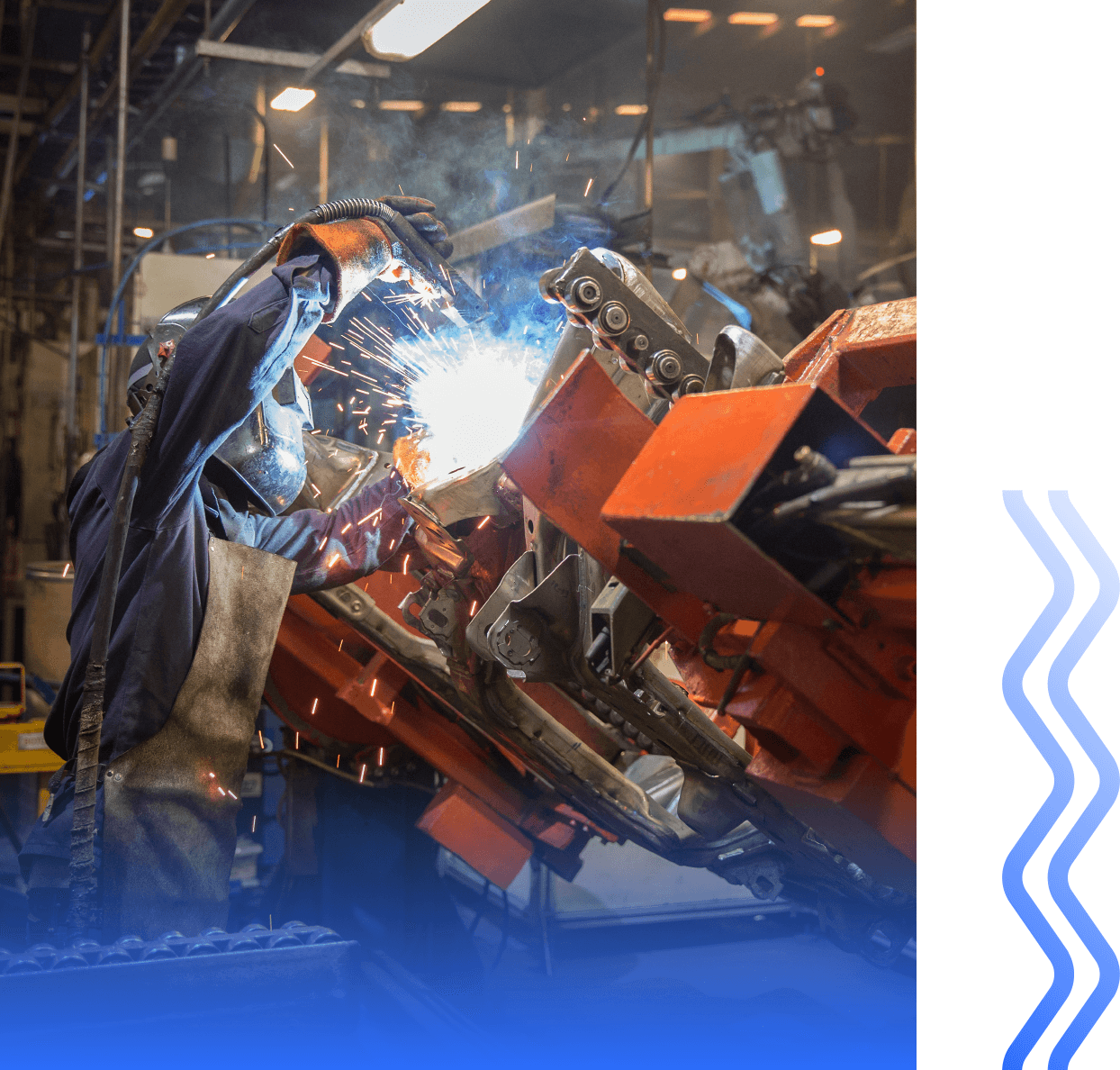

Safe operation

403-1, 403-2, 103-1, 103-2, 103-3

At Metalsa we value the well-being of our workforce, and we have put in place a variety of programs, policies, and initiatives to ensure a zero-rate accident and a safe work environment. In 2021, we launched our health and safety management system aligned to the ISO 45001:2018, the OSHA, and all relevant Mexican regulations. Two of our sites are currently ISO 45001:2018 certified, while the rest will complete their certification in 2022 and 2023.

+47,000

hours of Health & Safety training to members of our team

Key health initiatives in 2021

Vaccination campaigns

Blood donation campaigns

Ergonomic program

Psychology program

Prevention approach

We apply a preventive approach and a methodology based on the PDCA (Plan-Do-Check-Act) to improve our work environment and control risks, including policies, organization, planning assessment, due diligence, and improvement actions.

Safety around the clock and around the world

The staff take responsibility as a team for identifying and correcting unsafe practices. In 2021 our staff carried out 2,600 safety risk assessments.

Safety tutoring program

We provide training and one-to-one tutoring for new workers on safety risks ensuring that they know the risks involved in their specific roles and how to prevent them.

Rag (red, amber, green) safety program

This system has improved workstations’ overall safety. We label workstations as red, amber, and green according to their risk level and the operational level of experience required. For example, for workstations with a low-risk level (green), only one month of experience is required.

Health & Safety Training Program

At Metalsa, we work towards a safe operation throughout our business areas and sites. Thus, we have developed a robust H&S training program for all our personnel. The courses include incident management, emergency response, and safety in our hands.

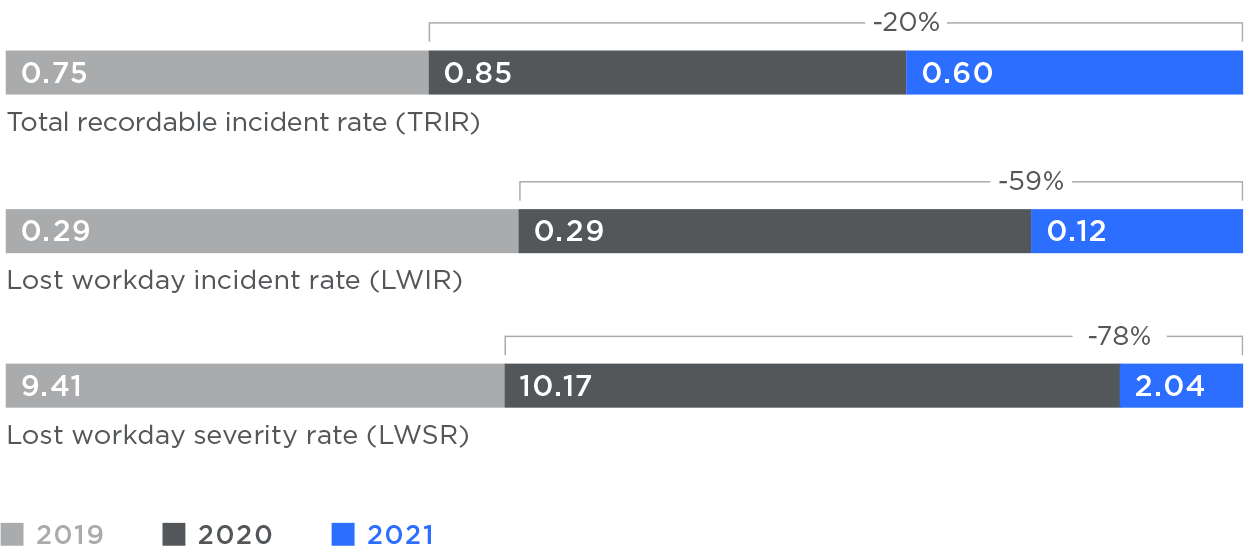

Our H&S results reflect all these measures and initiatives. Since 2019, our incident rate has been decreasing.

Incident and workday lost rates

Sustainable operation goals 2022

Increase the number of sites ISO 4500:2018 certified by 20%

Develop new requirements and a sustainability training for suppliers

Decrease our total recordable incident rate target by 11% vs the 2021 target