Environment

302-3, 302-4, 303-3, 303-4, 303-5, 305-1, 305-2, 305-4, 305-5, 306-3, 306-4, 306-5

We aim to promote and implement

actions and solutions that allow us

to reduce our environmental impact.

Resource management

Our great responsibility while we conduct operations is focused on protect the environment by creating awareness of the best practices and implementing actions to mitigate our environmental footprint.

Water

103-1, 103-2, 103-3, 303-3, 303-4

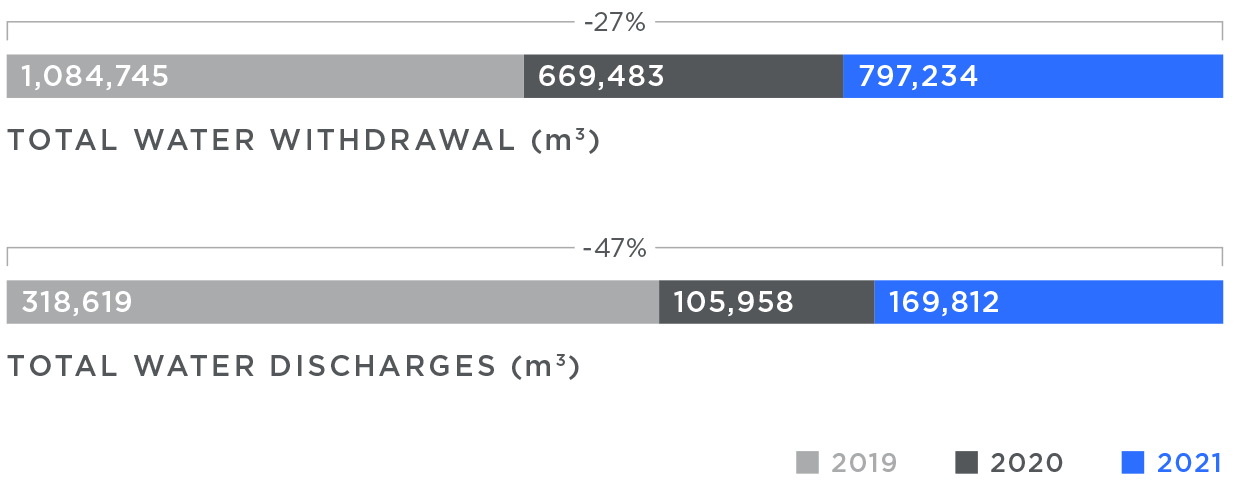

Our Environment, Health, and Safety unit oversees all our sites’ environmental performance and establishes annual goals. Every plant collects monthly reports of water withdrawals. During this reporting period, we reduced our water footprint.

Biological water treatment site

The treatment site, which opened in 2020, helps reuse water used in the painting process, which is the most water-intensive process of the plant. Thanks to this water treatment process, we reused 3,890m3 for the painting processes.

Waste

103-1, 103-2, 103-3, 306-3

Every site has its own waste management process; however, at a central level we organize and classify the overall waste generated by our productive and support processes.

Waste classification

Hazardous waste

Confined waste

Co-processed waste

Non - hazardous waste

Recyclable waste

Landfill waste

Waste generation

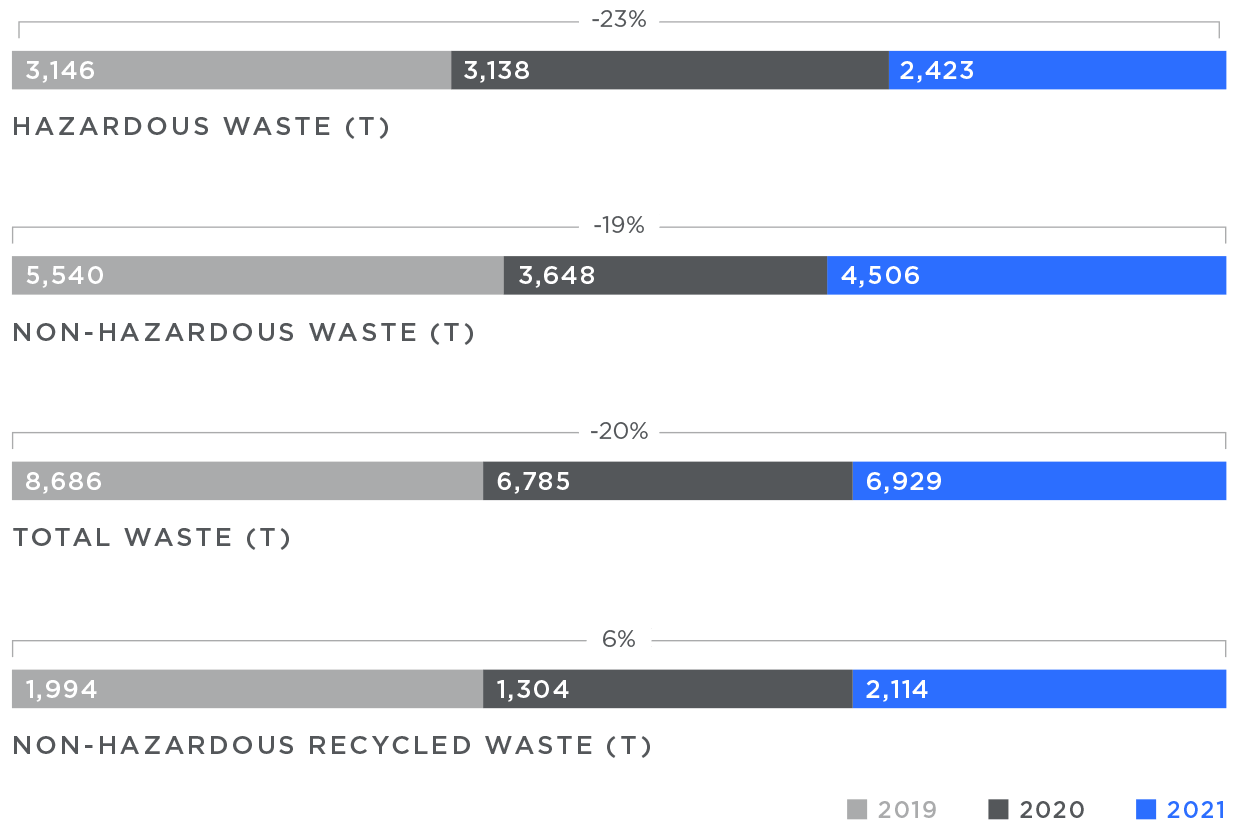

In 2021, carried out a series of projects to reduce the generation of waste and adopt a circular economy approach. Monitoring and measuring our waste help us to promote circular economy solutions aiming to become a zero-waste to landfill company.

Recycling metal slag

At our Saltillo site, we implemented a metal slag segregation program that has contributed to reduce our generation of hazardous waste by 6.8 tons per month. Through this project we collected a total of 82 tons of metal slag which was sold.

Reuse of welding inputs

We started this project with the objective to reduce waste and promote a reverse logistics approach. By returning cardboard containers, pallets and reels we reduced our waste by 56.26 tons.

1 In 2022 we will start accounting for Scope 3 emissions as Metalsa is planning to commit to the Science Based Targets initiative.

2 Data assured by ERM CVS. Please see the ERM CVS Assurance Statement.

Energy and emissions

103-1, 103-2, 103-3, 302-1, 302-4, 305-1, 305-2, 305-4, 305-5

Reducing our carbon emissions has become a key objective for our company. For this reason, we planned to join the Science Based Targets initiative (SBTi) in 2024, and this year, we moved the date forward to 2022. The SBTi will require us to set robust carbon reduction targets and thus, improve our energy efficiency strategies.

We are working on setting new GHG emissions and energy consumption targets to lead us to our Net-Zero objective.

Energy Consumption

|

2019 |

2020 |

2021 |

2021 vs 2019 |

|

|---|---|---|---|---|

|

Non-renewable fuel consumed (GJ) |

966,546 |

747,855 |

852,101 |

-11.84% |

|

Non-Renewable electricity consumed (GJ) |

1,128,785 |

864,727 |

896,251 |

-20.60% |

|

Renewable electricity consumed (GJ) |

49,823 |

43,393 |

52,660 |

5.69% |

|

Total energy consumption in the organization (GJ) |

2,145,154 |

1,655,975 |

1,801,012 |

-16.04% |

|

Annual energy intensity (GJ/mUSD) |

712 |

811 |

740 |

3.93% |

GHG emissions

|

2019 |

2020 |

2021 |

2021 vs 2019 |

|

|---|---|---|---|---|

|

Scope 1 emissions (tCO2e) |

88,639 |

49,109 |

70,200 |

-20.80% |

|

Scope 2 emissions (tCO2e) |

146,223 |

105,504 |

118,665 |

-18.85% |

|

Scope 3 emissions (tCO2e) |

N/A1 |

|||

|

Annual GHG total emissions (tCO2e) |

234,861 |

154,613 |

188,866 |

-19.58% |

|

Annual GHG Emissions intensity (tCO2e/mUSD) |

77.962 |

75.71 |

77.612 |

-0.45% |

Forklifts replacement

In 2020 our forklift fleet was made of 60% diesel and 40% gas, which contributed 916.5 tons of CO2. In 2021, we began to integrate electric technology in our processes reducing in 60% the CO2 emissions of our total fleet. In 2022 we will replace all of our forklift fleet with electric alternatives and expect to achieve a reduction of 93% of CO2 emissions compared to 2020.

Sustainability-linked bond

In April 2021, Metalsa issued its first Sustainability-Linked Bond with the target to reduce its greenhouse gas emissions intensity by 20% by 2031, considering a 2019 baseline. A progress review will take place in 2026. This initiative will drive our sustainability efforts and strategies Metalsa by having a meaningful and direct contribution to climate change.