About us

102-1, 102-2, 102-3, 102-4, 102-5, 102-6, 102-7, 201-1

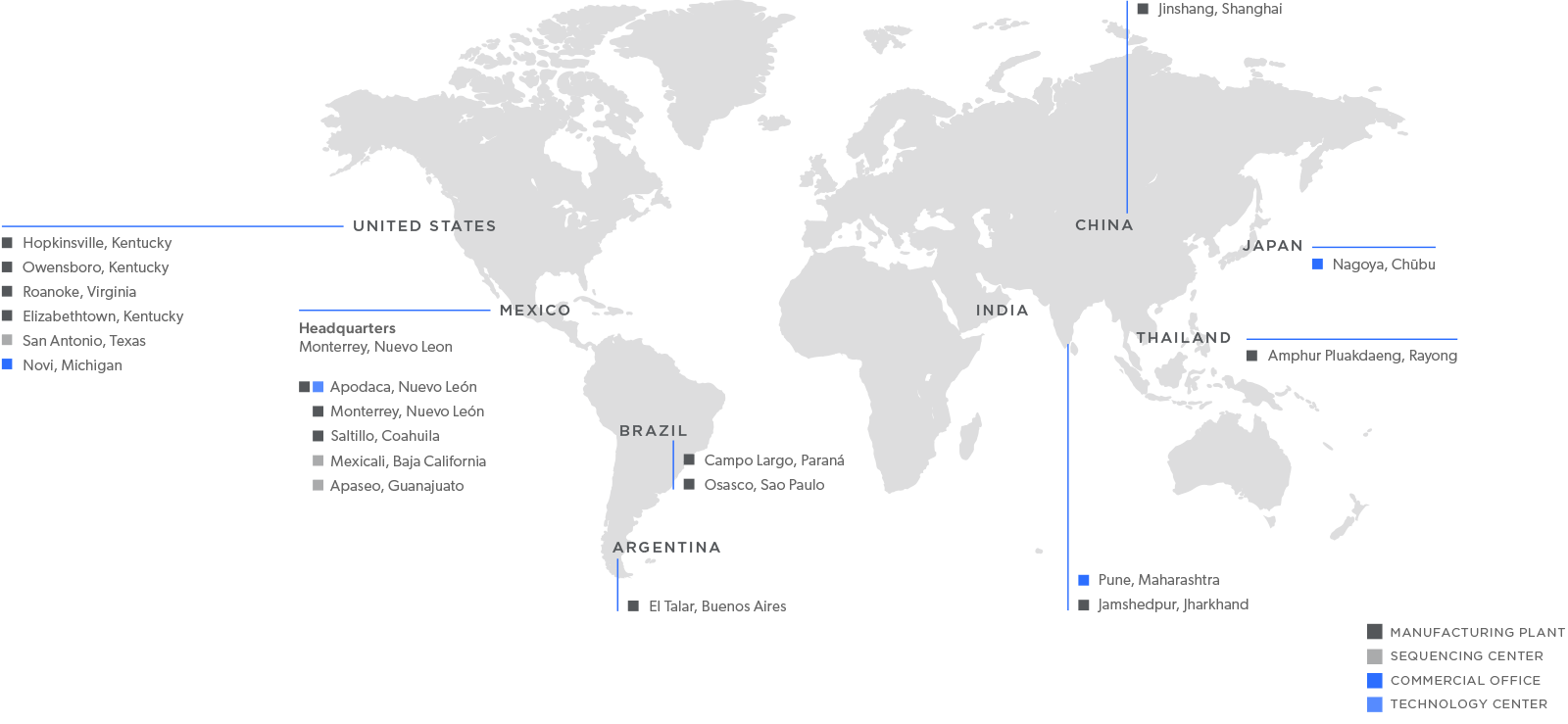

We are a company with a global presence, leading manufacturer of automotive components. Metalsa is a subsidiary of Grupo Proeza based in Monterrey, Nuevo Leon in Mexico, an industrial Mexican group owned, managed, and operated by the Zambrano family.

Metalsa in numbers

+60

years of

experience

+10

thousand

employees

8

countries

precense

12

manufacturing

plants

2.3

billion usd

in revenues

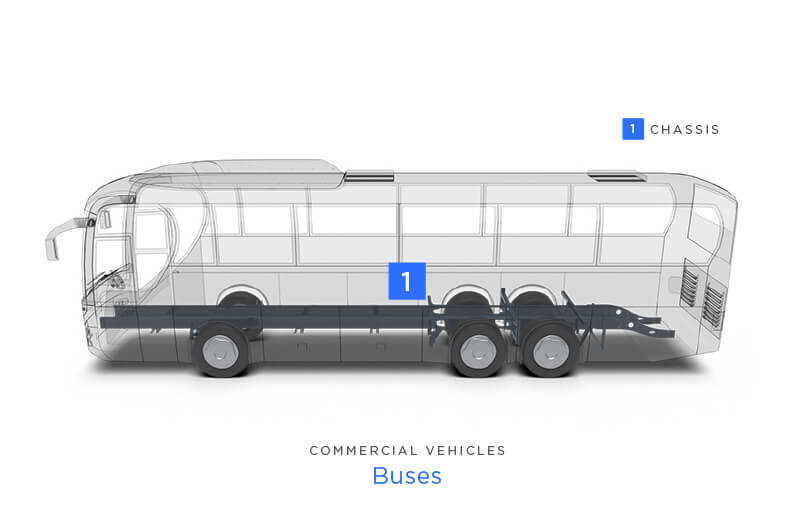

What we do?

102-2

We specialize in manufacturing chassis and body structure components for light and commercial vehicles sectors. Our products can be found in several brands and markets, from utility vehicles to luxury ones.”

Specialized services

102-2, 103-1

We also provide specialized services for the automotive industry, such as:

Design and development

Prototype and testing

Value and engineering

Production and launch

Our markets

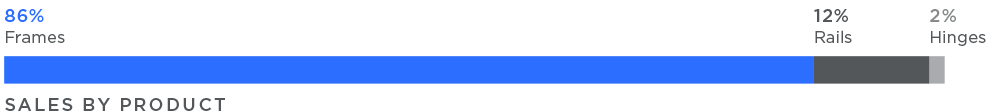

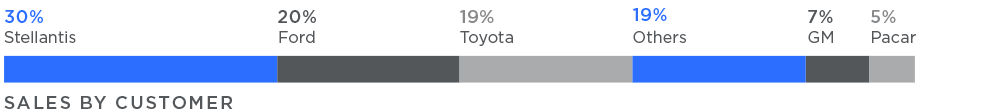

102-6, 102-7, 102-8

Revenues

102-7, 102-15, 201-1

Sales by region

|

Direct economic value generated and distributed (000) USD |

|

|---|---|

|

Direct economic value generated |

2,306,441 |

|

Income |

2,306,441 |

|

Economic value distributed |

2,201,006 |

|

Operating costs |

1,636,407 |

|

Employee wages and benefits |

458,694 |

|

Payments to government |

56,762 |

|

Payments to suppliers |

48,304 |

|

Community investment |

839 |

|

Economic value retained |

105,435 |

New opportunities on the horizon

We are focusing on structural solutions for electric vehicles and expanding our product portfolio. To capitalize on the growing electric vehicle market, we develop technology, build new capabilities, and launch new products. Thus, we expect to enter attractive markets by leveraging our core manufacturing, technology, and supply chain capabilities.

Record EBITDA year

in Metalsa history

All our suppliers were assessed

using social and environmental criteria

Metalsa is ISO 14001:2015

certified in all manufacturing sites

93% of our personnel received

Ethics and Integrity training

We launched our Sustainable

Community Development and

Social Investment Policy

Metalsa’s first Sustainability-Linked

Bond was issued, becoming one of the

first Tier-1 suppliers to issue it and the

first-ever USD-denominated Sustainability-

Linked Bond offering by a Mexican issuer

We launched our Diversity, Equity,

and Inclusion Strategy

More than 60% of our procurement

budget was spent on local suppliers

1,516 team members received Diversity,

Equity and Inclusion training

We carried out more than 2,500

risk assessments to protect the

safety of our personnel

More than 5,000 training courses

for our team were provided

throughout the year

We became a signatory of the UN

Global Compact, the world’s largest

corporate responsibility initiative

Our culture

102-16

Our vision

To become a leading mobility manufacturer of chassis & electrified solutions for the automotive, trucking, and off-highway industries.”

Our mission

To provide solutions for the global transportation industry and structures that help our customers move the world more efficiently, while protecting the environment and ensuring long-term economic and social value for our stakeholders.”

Our values

102-16

Person oriented

We work to build our own happiness and contribute to everyone else’s.

humble

We leverage our strenghts and overcome our weaknesses

Agile

We learn fast, adapt and move forward to add value

Transcendent

We ensure our actions have a positive impact

High Performing

We always collaborate and exceed expectations

Awards & recognitions

102-12

Excellent Quality

Performance Award

10 PPM Quality Award

Leader level - Supplier

Performance Metric (SPM)

Quality Excellence Award

Climate Change

Assessment

Water Security

Assessment

In 2021, we continued to excel as an automotive

industry supplier and received awards from

some of our key customers.

Safe products

103-2, 103-3

We are committed to manufacture the best products with exceptional quality and considering our client’s needs. Our products are assessed in quality, delivery, cost, warranty, durability, etc.

We implement a variety of processes to ensure safe and quality products:

Assess welding and geometry processes through our Welding System Assessment (CQI=15) Standard

Physical tests for prototypes and virtual simulations for all our designs

Verification of chemical substances and material compositions of our products through the International Material Data System (IMDS)